UC Davis leads breakthrough in ceramic nanoscience

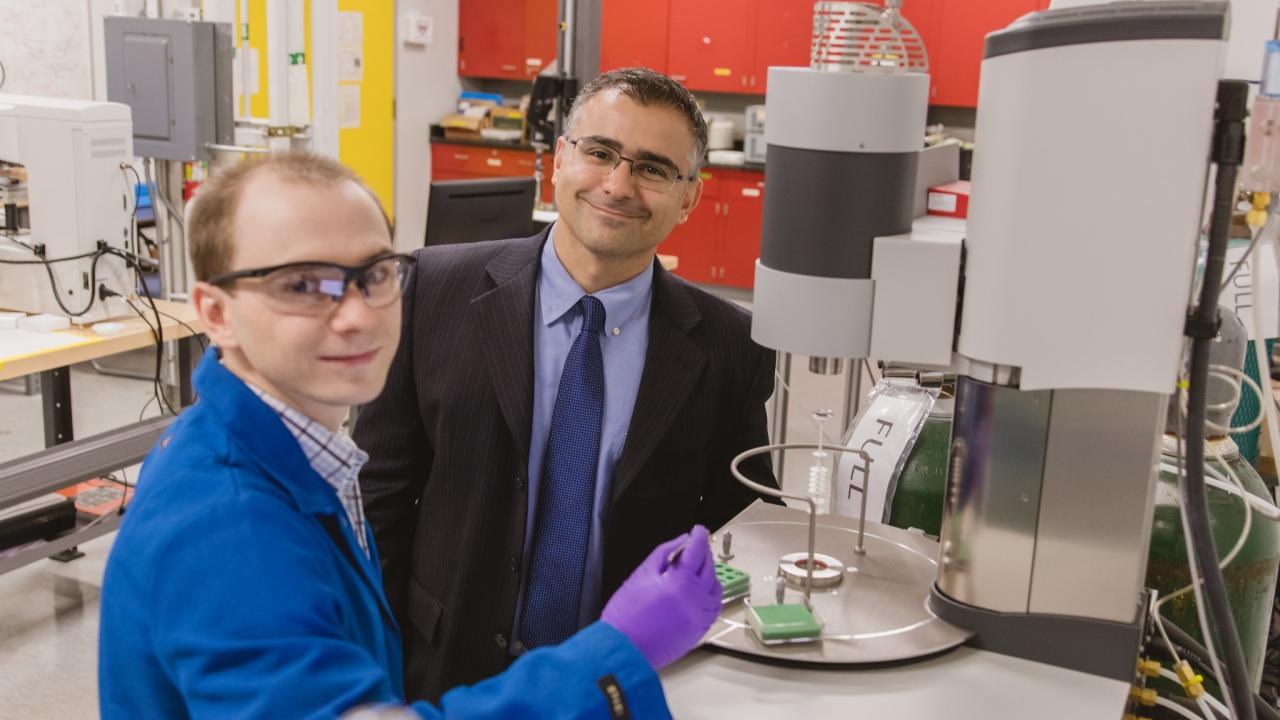

A new paper from professor Ricardo Castro’s group at UC Davis changes the understanding of how nanoscale dimensions affect the hardness of ceramics. The study, led by then Ph.D. student Arseniy Bokov, found that on nanoscale dimensions, ceramic materials give a false impression of softening because of an extensive network of almost invisible nanocracks.

“There’s no softening whatsoever—it’s just that cracks are so small and happen below the observable surface of the material and they give this false perception of softening,” explained Castro. “But most importantly, we found a potential way to fix it”.

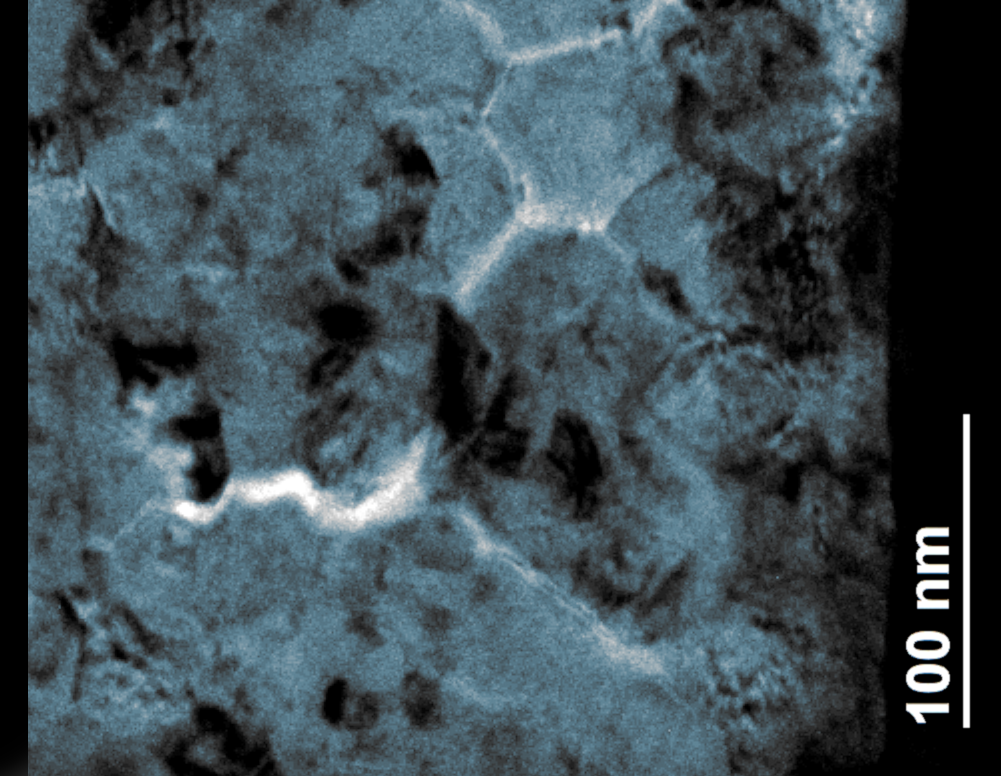

Ceramics are made up of millions of grains, individual arrangements of atoms in different orientations that come together to form the material. Grain boundaries, where the grains meet, are a double-edged sword. On one hand, they are often where cracks form and propagate, which can lead to material failure. On the other hand, they can absorb defects in the material, to the point that if grain sizes are small enough—meaning there are a lot of boundaries—the material gets harder and stronger.

Because of that, researchers look to the nanoscale as the way to make stronger ceramics. However, when grain sizes get below 20 nanometers, the hardness begins to decrease and the material appears to soften—something that wasn’t thought possible for the naturally brittle ceramics. Castro’s team decided to figure out what was happening and why.

The answer had to do with the energy of the grain boundary, which is an indirect measure of its strength. Strong grain boundaries have low energy, while weak ones have high energy. Castro and Bokov showed that as grains get smaller than 20 nm, the grain boundary energy increases remarkably, meaning the boundaries are much weaker and it’s easier for the grains to move against each other and eventually crack.

“This is the first time that grain boundary energy has ever been measured as a function of grain size,” said Castro. “Using the unique thermochemistry facilities at UC Davis, we expect to find many more connections between properties and interface energies”.

The study gives ceramics researchers a new understanding of how these materials perform and gives them the new goal of stabilizing grain boundary energy on the nanoscale to improve strength. Solving this problem will allow them to design stronger ceramics to meet the increasing demands of materials that can survive extreme environments on earth and in space.

“Now we know why this happens, so we can finally, really work on it,” he said. “You can’t do engineering it if you don’t understand; otherwise it’s just trial and error. Now that we understand, we can truly do engineering.”

The paper, “Size-induced grain boundary energy increase may cause softening of nanocrystalline yttria-stabilized zirconia,” was accepted by the Journal of the American Ceramic Society in October and will be published in a future issue. It was written in collaboration with Joao Rodrigues Neto, a visiting scholar from Brazil, and Feng Lin, a professor at Sun Yat-sen University in China. The work was funded by the Army Research Office Grant W911NF-17-1-0026, under the Materials Science Division.