Leveraging industry partnerships to teach remotely

The materials science and engineering (MSE) department is leveraging its industry connections and forging new partnerships to give students the best experience while teaching spring 2020 remotely. Professor Klaus van Benthem and Assistant Professor of Teaching Susan Gentry have worked with the software company COMSOL and the manufacturer KLA Corporation to keep students learning in this challenging environment.

“These kinds of partnerships strengthen our connection to industry and I think it’s something we need to build on in the future,” said van Benthem. “We may have had the fortunate occurrence in an unfortunate environment to have an opportunity to do that.”

Modeling Software for Senior Design

Every year, senior MSE students are given problems to solve for real-world clients with a design they build in teams and present at the annual Design Showcase. The project is a capstone of their undergraduate experience and, for many, a stepping stone to industry jobs.

However, Yolo County’s shelter-in-place order came the same day that they presented their design concepts to their peers. With the projects already in progress, the teams had to shift from building something to creating models of the design using engineering software.

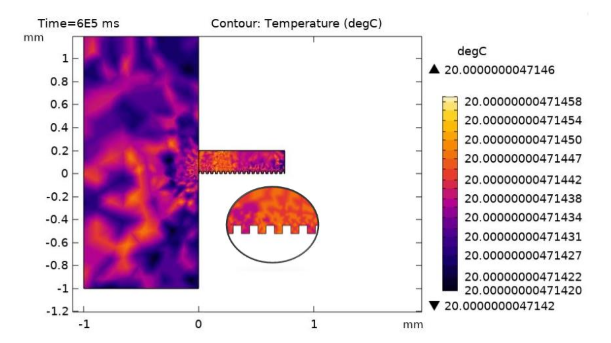

Accurate modeling in MSE requires simulations known as finite element models, which can be expensive. So van Benthem—this year’s senior design instructor—met with industry clients OSRAM and Keysight Technologies to work out a plan. He and OSRAM both use COMSOL Multiphysics in their labs and knew sales rep Michael Chai, so they contacted him and made a deal.

“This was a marvelous success—COMSOL got full trial licenses for every student,” said van Benthem. “These licenses are longer than typical trial licenses and have full capabilities. The students are now running finite element models at home from their kitchen tables.”

Thanks to COMSOL’s generosity, the class has been able to move their designs to simulations. Though there was a steep learning curve for most students, who had not previously done modeling, van Benthem thinks this could be the beginning of permanently integrating them into the curriculum, since many students will need these experiences in industry jobs.

Live Lab Demonstrations

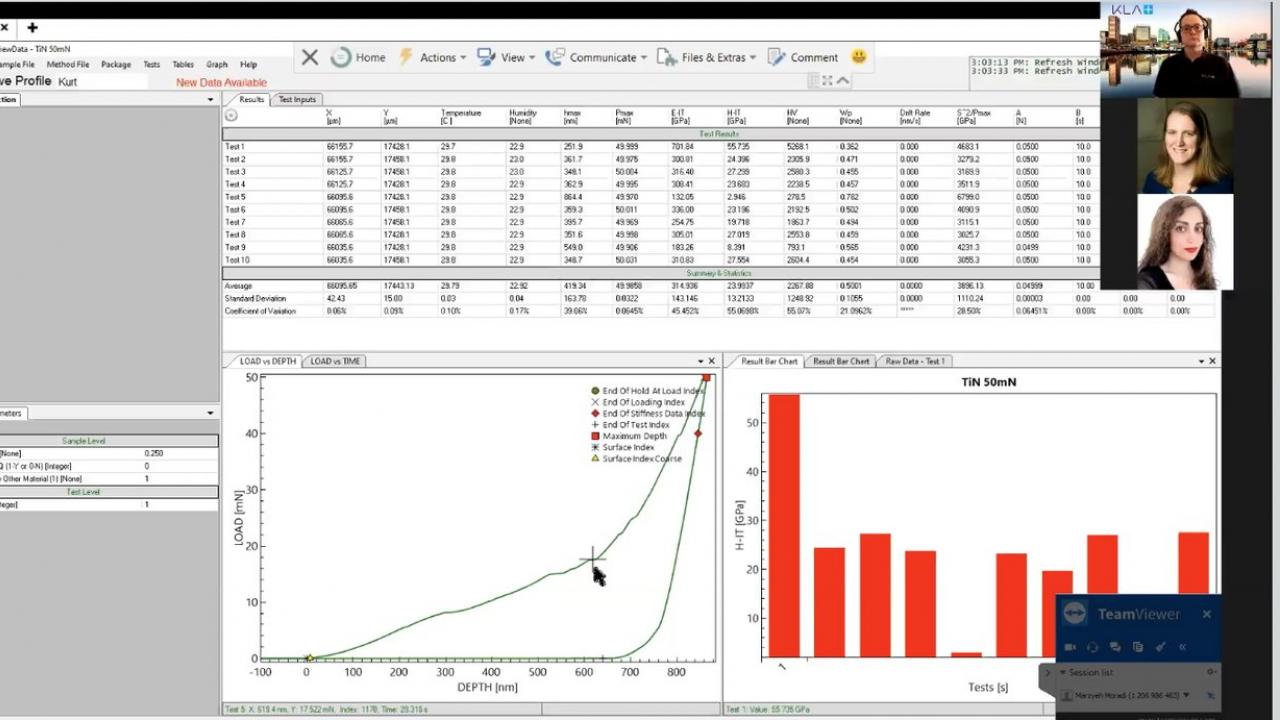

Van Benthem’s colleague Susan Gentry found similar success working with manufacturer KLA for her lab classes. In class, the students learn how to use two KLA uNano nanoindenter machines, which test material hardness.

She reached out to the company, hoping to use their pre-recorded demonstrations, but the company went the extra mile and did two live remote experiments for the class. KLA’s engineers showed them how the machines worked and how to set them up with real samples, with one running the equipment while the other moderated a Q&A with the students. The engineers gave students their test results so they were able to complete lab reports as if they had used the machines themselves.

“We were able to be her [Gentry’s] eyes and hands throughout that process,” said KLA’s Bryan Crawford. “I like that we can use the machine’s remote capabilities to educate our future researchers in this new environment.”

KLA’s visit to UC Davis was only their second live demonstration for universities, but they have already lined up more in the near future, and Crawford says they are looking at how to expand this service, even after the pandemic, since the machines can be accessed from anywhere and at any time of the day.

With the success Gentry and van Benthem have seen, the department feels that these partnerships can be a jumping off point for more collaborations with industry.

“Things are different, but we’re trying to take advantage of the time to do things that we might not have otherwise,” said Gentry. “It brings new opportunities for students to learn things and develop skills that they need.”